The Greenforage/Robustrack team recently installed an NIR sensor on a combine harvester. As an introduction, here’s a description of sensor:

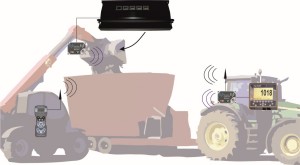

The EvoNIR 4.0 Analyzer with ISOBUS protocol can be connected to any virtual terminal with built-in ISOBUS task controller and can be installed on forage harvesters, combines, balers, forage wagons, slurry tankers, compactors, feed mixers and portable in a carrying case.

Our customer has an extensive arable farming business based near Grantham, Lincolnshire, with a large proportion of the year’s cropping made up of milling grade wheat and malting barley. They run a modern fleet of machinery and currently utilise arable farm management software (Possibly Gatekeeper) being up to date on modern and progressive farming strategies.

Why NIR?

They already use handheld NIR on the farm for assessing grain that is in storage on farm before it is sold to know if it will meet milling grade for the wheat and malting grade for the barley. It also gives a moisture content for the sample for storge.

Why on the combine?

They have installed the NIR sensor on the combine for a few reasons but the main ones are:

- to map field nutrients for more accurate fertiliser application

- and most importantly is to have a live nutrient analysis of protein in wheat and barley.

All milling wheat over 13% protein is sold at a premium, the lesser grade goes for feed at a lower price. With the NIR they will have a real time % of protein in the wheat which will allow them to store the milling grade wheat and feed wheat in different sheds before it is sold, this reduces the amount of high protein wheat being blended into the lower grade feed wheat and going for feed at the lower price. Similarly malting barley needs a protein of 10-10.9% so this can be determined at the point of harvest and be divided into different grain stores depending on the protein percentage.

- Another benefit of the NIR sensor for the customer is the accurate moisture readings.

Anything over 15% moisture when combined needs drying before storage so it doesn’t go mouldy, logistically they will know at the time it is combined the accurate moisture reading and if it is suitable to go straight into the dry storage or into the wet storage and be put through the grain dryer dried down to 15%.

Machine

It was installed on a 2016 Claas Lexion 780 TT Rotary combine which runs Trimble GFX 750 display and autosteer. Installation of the NIR sensor unit is on the clean grain elevator which leads into the grain tank giving a clean and accurate sample of what is being harvested. All wiring for the system follows factory wiring harnesses and links to the Trimble display through ISOBUS.

The NIR system has its own GPS and modem so data can be imported and exported wirelessly from the Field Trace software the farm has been set up on.

Field Trace allows the farm to map out the field and assign names after the harvest has been completed, giving full colour overlay on nutrient and moisture analysis on a detailed map.

Customer Feedback

The system was found by all to be very easy to use and intuitive, exactly what is needed for farm software with multiple users. In addition, the ease of installation was a great benefit with an equally easy set up and system test.